Why Cooling Tower Matters

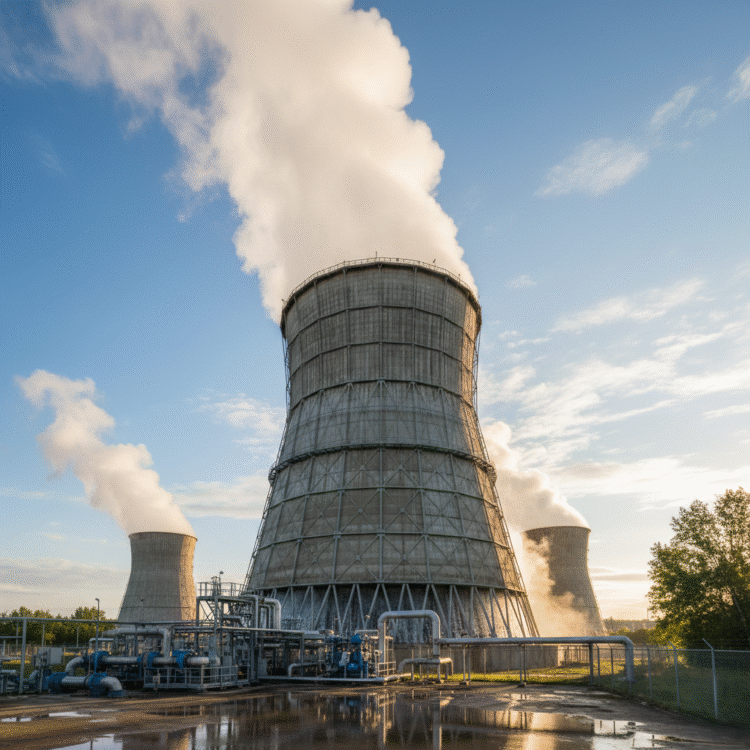

Cooling Tower aapke industrial process ka heart hota hai. Iska kaam excess heat ko system se nikalna hai. Agar yeh system theek se kaam nahi karta, toh aapki puri production line ki efficiency reduce ho jaati hai aur energy consumption badh jaati hai.

Lekin cooling tower hamesha 3 bade dushmano se ghira rehta hai: Scaling, Corrosion, aur Biofouling (Algae/Bacteria). Agar inhein control nahi kiya gaya, toh Reduced Heat Transfer ki problem aayegi. Hum Bluewello par Cooling Tower Water Treatment mein expert hain. Is article mein, hum aapko woh 4 essential steps batayenge jisse aap apne cooling tower ki life aur performance dono badha sakte hain.

Step 1: Biofouling: The Silent Killer

Cooling Tower Mein Algae Aur Bacteria Ka Khatra

Boiler aur RO ke mukable, Cooling Tower mein biological growth (algae aur bacteria) ki problem sabse zyada hoti hai, kyunki yeh system open atmosphere mein chalta hai.

Algae Problem: Algae tower ke fills aur basin ko block kar deta hai.

Bacteria (Biofilm) Problem: Bacteria heat exchanger surfaces par ek chipchipi film (biofilm) bana dete hain. Ye biofilm heat transfer ko buri tarah rokta hai, jisse aapki chiller efficiency down ho jaati hai. Is biofilm ko Cooling Tower Algae Removal chemicals se eliminate karna zaroori hai.

Step 2: Biocides Ka Sahi Istemal Zaroori Hai

The Biocide Strategy

Biofouling se bachne ka ekmatra tarika hai Cooling Tower Biocide ka regular use karna. Biocides do tarah ke hote hain, aur dono ka use zaroori hai:

Oxidizing Biocides (Chlorine/Bromine-based): Ye tezi se kaam karte hain aur cells ko oxidize karke khatam kar dete hain. Lekin ye zyada samay tak system mein nahi rehte.

Non-Oxidizing Biocides (Bluewello BWBC-01/02): Ye dheere-dheere kaam karte hain aur cells ki growth ko rok kar system ko lambe samay tak protect karte hain.

Rotation is Key: Sabse effective treatment hai Biocide Rotation. Algae aur bacteria ko chemical se aadat na ho jaye, isliye aapko periodically oxidizing aur non-oxidizing biocides ko rotate karna chahiye. Isse aap Cooling Tower Algae Removal ko permanent bana sakte hain.

Step 3: Scale Aur Corrosion Ko Control Karein

Two-in-One Protection

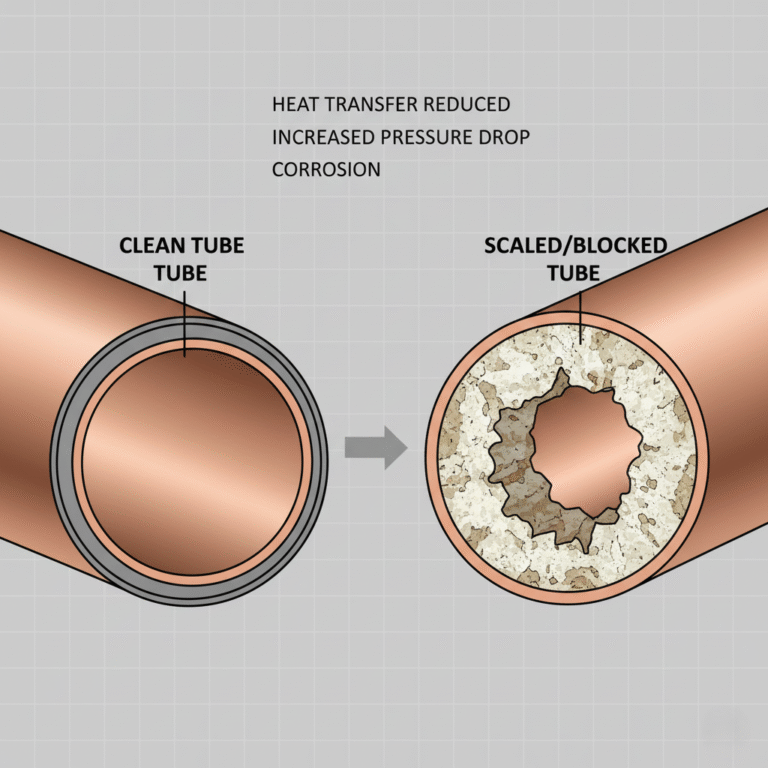

Biological growth ke saath hi Scaling aur Corrosion ko bhi control karna bahut zaroori hai:

Scaling Control: Cooling tower mein water continuously evaporate hota rehta hai, jisse minerals (Calcium, Magnesium) ki concentration badh jaati hai. Isliye, high-quality Cooling Tower Antiscalant ka use zaroori hai, jo in minerals ko pipe walls par jamne se roke.

Corrosion Control: Cooling tower mein dissolved oxygen ki matra zyada hoti hai, jisse metal pipes mein rust lagne ka khatra badh jaata hai. Corrosion Inhibitor for Cooling Tower metal ki surface par ek protective layer bana dete hain, jisse metal ki life badhti hai.

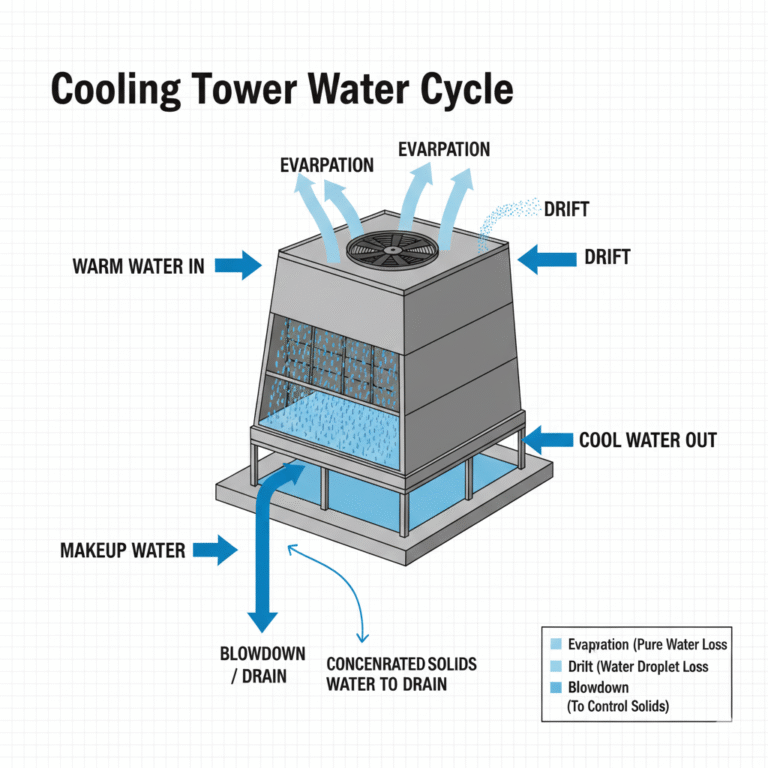

Step 4: Cycles of Concentration (COC) Ko Manage Karein

Efficient Water Management

Cycles of Concentration (COC): COC batata hai ki aap paani ko kitna efficiently use kar rahe hain. Sahi Cooling Tower Water Treatment ki madad se aap COC ko high rakh sakte hain (kam water waste).

Blowdown Management: Blowdown process se system mein jama hue concentrated minerals ko bahar nikalna zaroori hai. Sahi chemicals ka use blowdown ki zaroorat ko optimize karta hai, jisse aap water consumption kam kar sakte hain.

Conclusion

Cooling Tower ki efficiency ko maintain karne ka matlab hai Biofouling, Scaling, aur Corrosion par ek saath control rakhna. Cooling Tower Biocide ka regular use aur sahi Antiscalant dosing aapke heat exchanger ko clean rakhega aur Reduced Heat Transfer ki problem ko khatam karega.

Agar aap apne plant ke liye specialized Cooling Tower Water Treatment Chemicals chahte hain, toh Universal Experts (Bluewello) ki team se contact karein. Hum aapke local water quality aur system type ke anusaar best chemical solution tayyar karte hain.