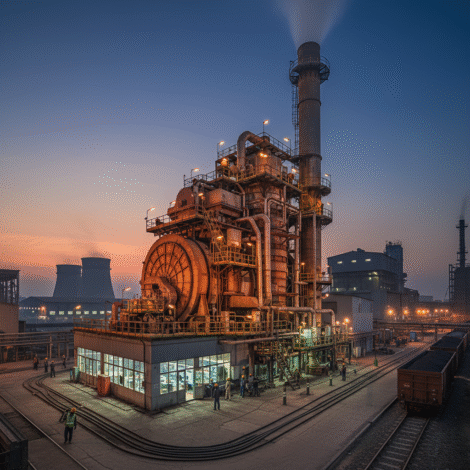

Introduction: High Stakes, High Costs

Har industrial plant mein, boiler ki running cost sabse zyada hoti hai. Lekin agar aapka boiler apni poori efficiency se kaam nahi kar raha hai, toh aap har din hazaron ka fuel waste kar rahe hain. Is low efficiency ka mukhya karan hai internal problems— Scaling, Sludge, aur Corrosion.

Hum Bluewello par jaante hain ki sahi Boiler Water Treatment Chemicals ka use sirf equipment ki safety nahi, balki seedhe aapki bottom line (profit) ko improve karta hai. Is article mein, hum woh 4 tarike batayenge jisse aap apne boiler ki performance ko top-notch rakh sakte hain.

Step 1: Membrane Failure Ke Karan Ko Samjhein (Understanding the Enemy)

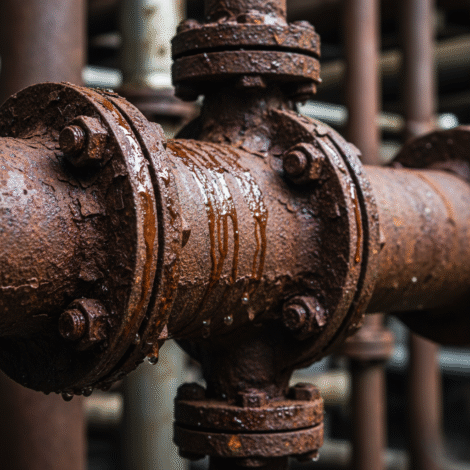

The Main Culprit: Scaling aur Fouling

Membrane fail hone ke do bade karan hote hain: Scaling aur Fouling.

Scaling (The Mineral Buildup): Jab feed water mein Calcium, Magnesium, Barium, aur Silica jaise minerals ki concentration badh jaati hai, toh ye membrane ki surface par jam jaate hain. Isse membrane ke pores band hone lagte hain, jise RO Membrane Scaling kehte hain. Iska pehla sanket hota hai RO Pressure Drop aur output water ki quality kharab hona.

Fouling (The Biological Attack): Ye organic matter, dust particles, ya micro-organisms (bacteria, algae) ke jamaav se hota hai. Biological fouling se membrane chipchipi ho jaati hai aur uski filtering capacity khatam hone lagti hai. Ye problem aksar RO Plant Fouling ke roop mein dikhti hai.

Jab tak aap in dono dushmano ko nahi samjhenge, tab tak sahi treatment nahi kar payenge.

Step 2: Sahi Pre-Treatment Zaroori Hai

Filtration: Pehla Safety Barrier

Membrane ki life badhane ka sabse pehla aur zaroori kadam hai Pre-Treatment. Membrane se pehle filtration kitna achha hai, isse decide hota hai ki uspar kitna load aayega.

Filter Quality Check: Hamesha check karein ki aapke Multi-Media Filter (MMF) aur Activated Carbon Filter (ACF) theek se kaam kar rahe hain ya nahi.

SDI Monitoring: Feed water ka Silt Density Index (SDI) hamesha monitor karte rahein. Agar SDI value zyada hai, toh membrane par load badhega, isliye Pre-Treatment ko turant improve karein.

Achhi pre-treatment se membrane ki cleaning frequency kam ho jaati hai.

Step 3: Sahi RO Antiscalant Ka Chunav Aur Dosing

The Antiscalant Strategy

Scaling se bachne ka sabse effective tareeka hai RO Antiscalant ka use karna. Antiscalant ek aisa chemical hai jo minerals ko membrane par jamne se pehle hi isolate kar deta hai. Lekin sirf use karna kaafi nahi, sahi Antiscalant dosing bahut important hai.

Right Product: Aapke feed water ki quality aur mineral composition ke according sahi Industrial Antiscalant chunein. Bluewello mein, hum specific water quality ke liye customized antiscalants dete hain, jo market ke generic products se kahin behtar result dete hain.

Accurate Dosing: Antiscalant ko hamesha uski sahi matra (dosing rate) mein hi use karein. Kam dosing se scaling nahi rukega aur zyada dosing se chemical ka kharcha badhega. Dosing hamesha feed water flow ke anusaar honi chahiye.

Expert Tip: Antiscalant ki effectiveness ko regularly check karein. Agar aapka RO Pressure Drop ab bhi ho raha hai, toh turant Antiscalant ki quality ya dosing check karein. Sahi aur consistent RO Antiscalant ka use membrane ki life mein 60% tak ka improvement la sakta hai.

Step 4: Time Par Cleaning Karna Na Bhulein

Periodic Chemical Cleaning

Bhale hi aap kitna bhi achha Antiscalant use kar rahe hon, thode samay baad membrane par kuch buildup zaroor hoga. Isliye Periodic Chemical Cleaning bahut zaroori hai.

Jab Zaroori Ho: Cleaning tab karni chahiye jab permeate flow 10-15% kam ho jaye ya differential pressure 10-15% badh jaye.

Sahi Chemical: Cleaning ke liye hamesha high-quality RO Membrane Cleaner ka use karein. Ye cleaners do tarah ke hote hain: Acidic (Scaling ke liye) aur Alkaline (Organic Fouling ke liye).

RO Membrane Cleaning Procedure: Hamesha manufacturer ki sifarish kiye gaye temperature aur pH par hi cleaning karein. Galat temperature ya chemical strength se membrane permanently damage ho sakti hai.

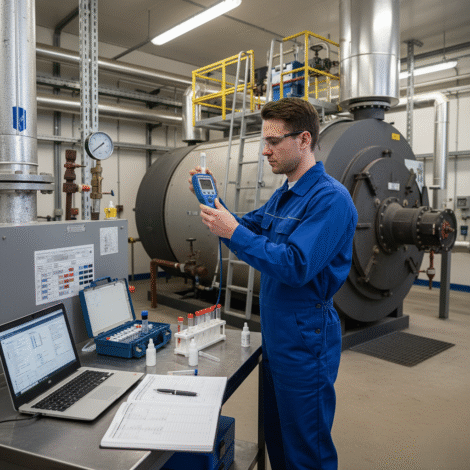

Step 5: System Monitoring Aur Log Maintenance

Regular Monitoring is Essential

System ki regular monitoring aur data logging aapki sabse badi madadgar hai.

Daily Log: Har din ka feed pressure, permeate flow, concentrate flow, aur TDS check karein. Agar koi bhi reading suddenly badalti hai, toh turant action lein.

Chemical Inventory: Hamesha check karte rahein ki aapka RO Water Treatment Chemicals ka stock available hai ya nahi. Emergency ke waqt stock khatam hona bahut bada nuksaan kar sakta hai.

Conclusion

RO membrane ki life badhana sirf replacement cost kam karna nahi hai, balki aapke plant ki operational efficiency ko maintain karna bhi hai. Sahi RO Antiscalant ka chunav, achhi pre-treatment, aur time par cleaning hi membrane ko lambe samay tak healthy rakhti hai.

Agar aap apne industrial RO plant ke liye sabse behtar aur customized Industrial Antiscalant solution chahte hain, toh aaj hi Universal Experts (Bluewello) ki team se contact karein. Hum aapke water ki quality ke anusaar best chemical solution suggest karenge.