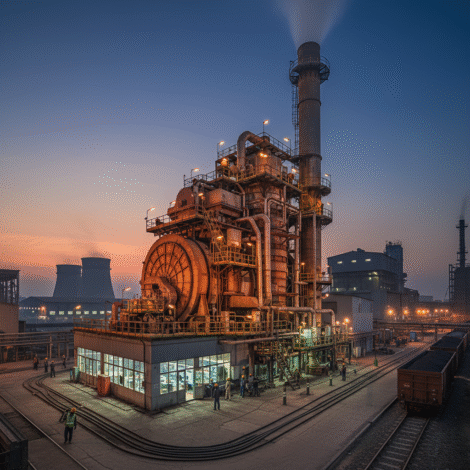

Introduction: The Necessity and the Risk

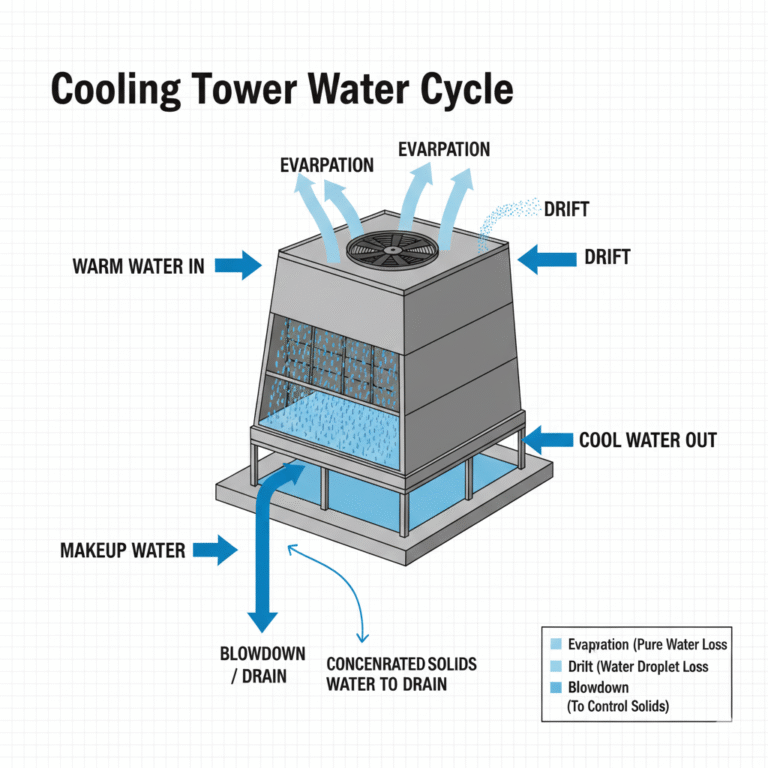

Har industrial facility mein HCL, Caustic Soda, aur Descaling Chemicals jaise powerful raw chemicals ka istemal zaroori hota hai. Ye chemicals aapke equipment ko saaf aur efficient rakhte hain.

Lekin in chemicals ki taakat inhein khatarnak bhi banati hai. Galat Caustic Soda Handling ya Acid ka istemal bade hadson, metal damage, aur serious injuries ka karan ban sakta hai. Hum Universal Experts (Bluewello) par, safety ko sabse upar rakhte hain. Is article mein, hum aapko woh 5 Golden Rules batayenge jo aapke aur aapke staff ki hifazat ke liye bahut zaroori hain.

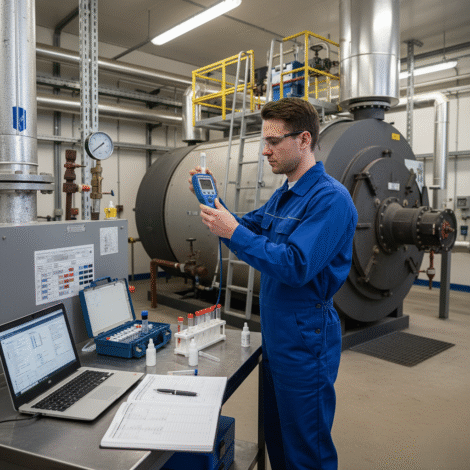

Step 1: The Golden Rule: PPE Hai Pehli Hifazat

Zaroori PPE for Chemical Handling

Safety ki shuruat hamesha Personal Protective Equipment (PPE) se hoti hai. Kabhi bhi, kisi bhi chemical ko bina PPE ke handle na karein.

Hands & Skin: Hamesha Chemical Resistant Gloves (Nitril ya Butyl Rubber) use karein. Regular kapde ya leather ke gloves chemical ko absorb kar lete hain.

Eyes & Face: Full Face Shield aur Safety Goggles dono zaroori hain, khaaskar jab aap dilution ya transfer kar rahe hon.

Body & Clothes: Apron aur Boots chemical resistant hone chahiye.

Breathing: Agar chemical fumes nikalte hain (Jaise HCL), toh Sahi Ventilation zaroori hai. Agar ventilation na ho, toh Respirator Mask ka use karein.

Step 2: Acids Ka Safe Application Guide (Jaise HCL)

HCL for Cleaning Aur Descaling

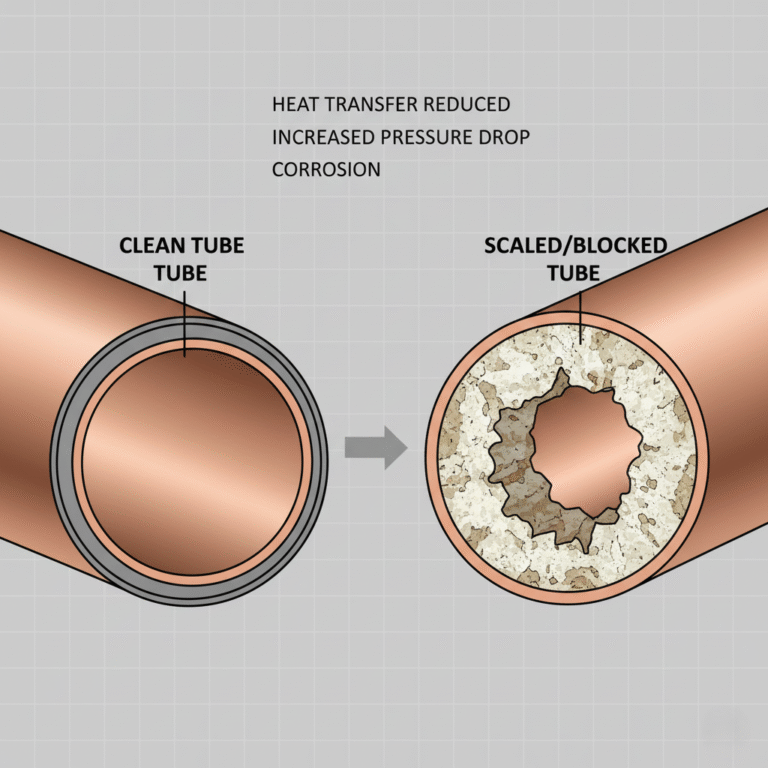

Acidic chemicals jaise Hydrochloric Acid (HCL) aur Citric Acid ka use Descaling (mineral deposits hatane) ke liye hota hai.

Dilution Rule: Acid ko hamesha paani mein milayein (Add Acid to Water – A.A.W.), na ki paani ko acid mein. Agar aap paani ko acid mein dalenge, toh chemical reaction bahut tezi se hogi aur splattering ho sakti hai.

Ventilation: HCL use karte samay accha ventilation rakhein, kyunki iski fumes saans lene mein dikkat paida kar sakti hain.

Testing: Descaling ke baad, surface ko neutralise karna zaroori hai (Step 4 dekhein). Citric Acid Descaling halka aur safer option hai, lekin ismein bhi PPE zaroori hai.

Step 3: Alkalies Ka Safe Handling Guide (Jaise Caustic Soda)

Caustic Soda Handling Aur Degreasing

Alkaline chemicals jaise Caustic Soda (Sodium Hydroxide) ka use degreasing aur organic matter ko saaf karne ke liye hota hai.

Handling Heat: Jab Caustic Soda flakes ko paani mein milaya jaata hai, toh woh bahut zyada garmi paida karta hai. Hamesha dhire-dhire aur thande paani mein milayein.

Slippery Surface: Alkaline chemicals surfaces ko bahut chikna (slippery) bana dete hain. Cleaning area ko hamesha turant dhoyen taaki slip hone ka khatra na ho.

Skin Contact: Agar Caustic Soda skin par pad jaye, toh turant zyada paani se dhoyen.

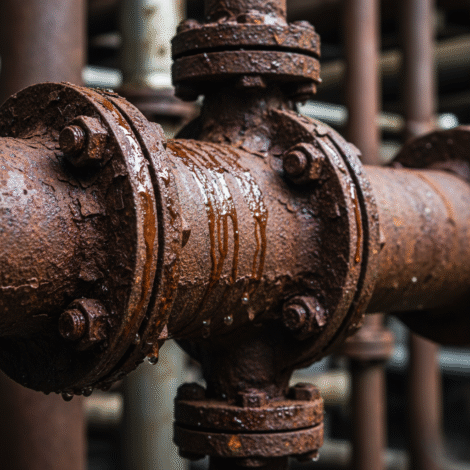

Step 4: Storage, Segregation Aur Disposal

Store Safe, Dispose Safe

Sahi Safe Storage of Industrial Chemicals hadson ko rokta hai.

Segregation: Acid aur Alkali chemicals ko hamesha alag-alag (separate) jagah par store karein. Agar ye mil jayein toh dangerous reaction ho sakta hai.

Temperature: Chemicals ko direct sunlight aur high temperature se door rakhein.

Disposal: Chemicals ko hamesha government/local guidelines ke anusaar hi dispose karein. Unhe drain mein na bahayein.

Step 5: Emergency Protocols

Ready For The Worst

Neutralization: Acid spill hone par Baking Soda ya Soda Ash (milder alkali) ka use karein. Alkali (Caustic Soda) spill hone par Citric Acid ya Vinegar (milder acid) ka use karein.

Eyewash Station: Work area ke pass hamesha ek functional Eyewash Station zaroor hona chahiye.

First Aid: Turant doctor se consult karein, bhale hi injury chhoti lage.

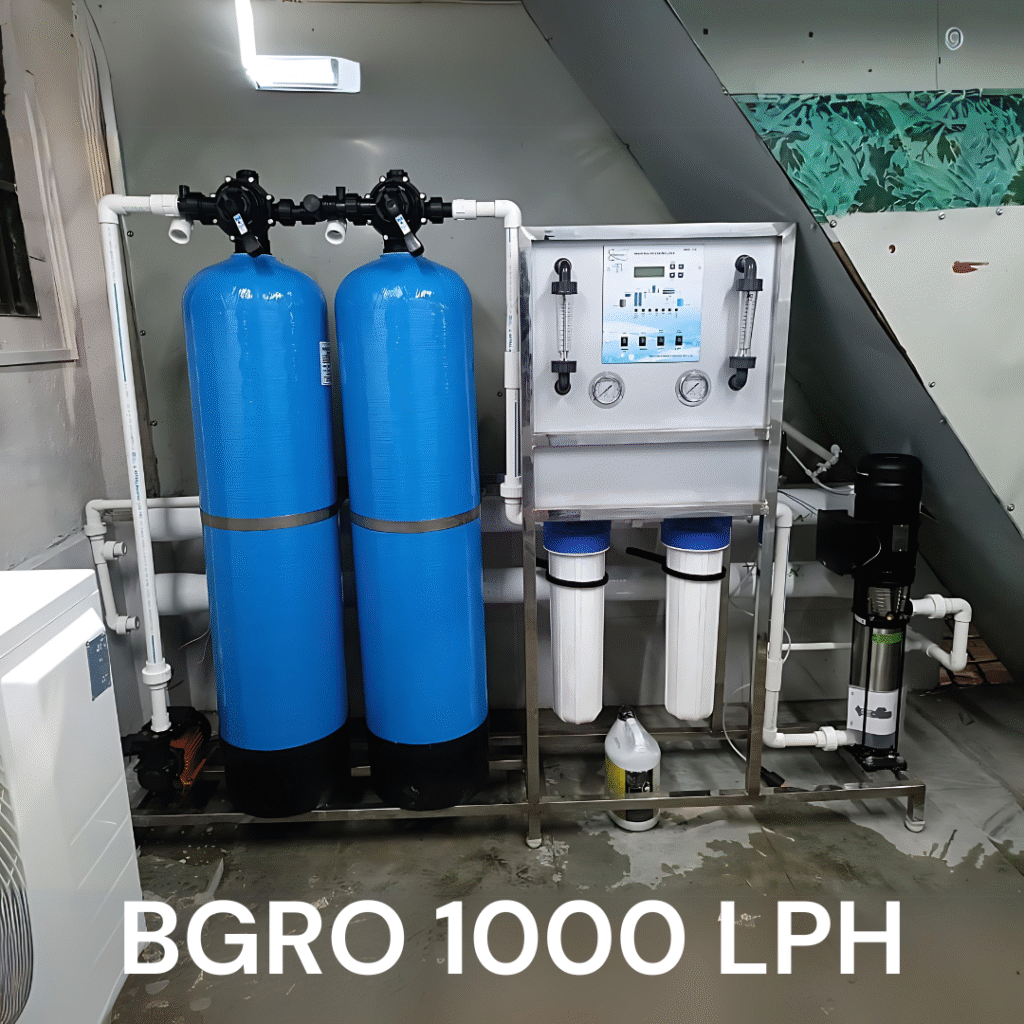

Conclusion

Industrial Chemical Safety Tips sirf rules nahi, balki aapki aur aapke plant ki suraksha ki guarantee hai. Sahi PPE for Chemical Handling, dilution rules, aur Safe Storage of Industrial Chemicals se aap har tarah ke hadson se bach sakte hain.

Agar aap high-quality aur sahi safety documentation ke saath Industrial Cleaning Chemicals chahte hain, toh Universal Experts (Bluewello) se contact karein.